Product Description

HangZhou CHINAMFG auto parts co limited has more than 5000 square warehouse for wholselling

spare parts in china and exporting , we give wholselling quotation as ur quantity , price very competitive .

we have more than 10 years experience of spare parts

we deal in faw CHINAMFG CHINAMFG beiben CHINAMFG jac dayun heavy duty spare parts and yutong CHINAMFG higer bus spare , liugong CHINAMFG cat machine spare parts

we have professional team of purchasing , cleaning customs and doing all exporting certification

best price and well laoding for customers

| what we have : | weichai ,faw CHINAMFG CHINAMFG CHINAMFG ect spare oem part no system , customer only show us chassis no , we can give u exact part no and spare size |

| what we will do: | we will honest to each customers of quality and quantity and give best suggestion |

| what we have in stock: | fast moving items of filter , fan belt ,body spare parts ,sensor valve has in stock for container bulk order ,we need to take 15-30 working days |

| what our payment: | LC and tt , long time honest distribution give credits |

| what our quality: | original , oem customers package ,copy A B C |

| what our package: | wooden box , pallet with plastics , paper box |

| what our exporting port : | HangZhou ZheJiang port and make door to door to customers warehouse |

| why our price has advantage: | we are in HangZhou city where is biggest spare parts distribution city in china and spare parts manufacture center !!!!! |

pls feel free to contact us by made in china , waiting ur inquiry and come china to visit us ~~~~~~ /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle |

|---|---|

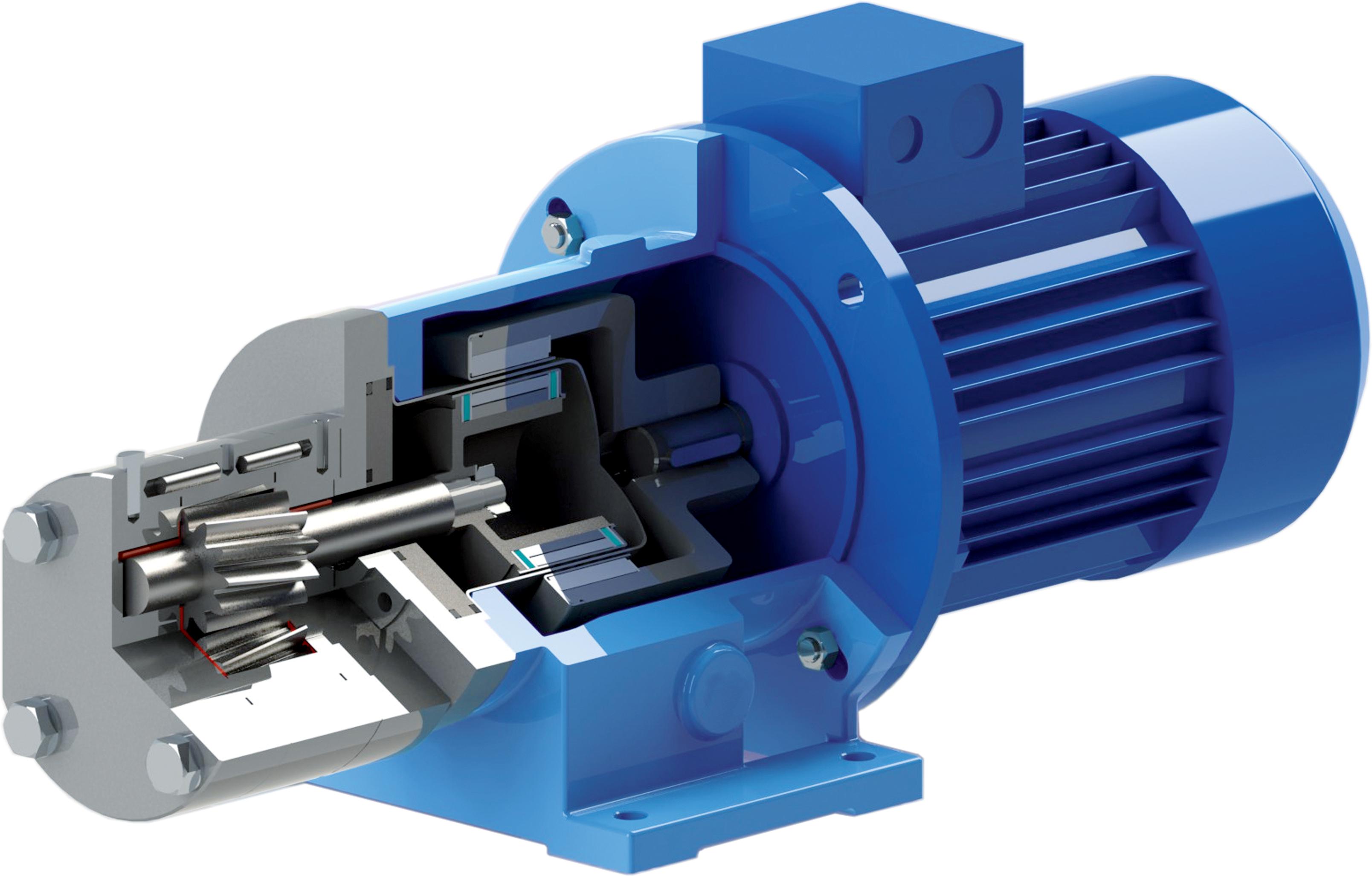

| Function: | Distribution Power, Clutch, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Soft Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does a gear pump handle variations in fluid viscosity?

A gear pump is capable of handling variations in fluid viscosity effectively. Here’s a detailed explanation:

1. Positive Displacement Operation:

One of the key features of a gear pump is its positive displacement operation. Regardless of the fluid’s viscosity, the pump delivers a consistent flow rate with each revolution of the gears. The pump traps and displaces a fixed volume of fluid with each rotation, ensuring that the same amount of fluid is moved regardless of changes in viscosity. This positive displacement action allows the gear pump to handle variations in fluid viscosity and maintain accurate and consistent fluid delivery.

2. Viscosity Range:

Gear pumps are designed to handle fluids with a wide range of viscosities. They can effectively handle low-viscosity liquids as well as highly viscous fluids. The pump’s positive displacement mechanism ensures that the fluid is moved at a consistent rate, regardless of its viscosity. This makes gear pumps versatile and suitable for various applications where fluids of different viscosities need to be pumped.

3. Self-Priming Capability:

Gear pumps have a self-priming capability, which means they can draw fluid into the pump without the need for additional priming mechanisms. This self-priming feature allows gear pumps to handle fluids of varying viscosities, including thicker or more viscous fluids that may be difficult to pump with other types of pumps. The gears create a vacuum effect that draws the fluid into the pump, enabling efficient operation even with varying viscosities.

4. Temperature Considerations:

Fluid viscosity can be affected by temperature variations. Gear pumps are designed to handle a wide range of temperatures, allowing them to accommodate changes in fluid viscosity due to temperature fluctuations. It’s important to consider the temperature limits specified by the pump manufacturer to ensure optimal performance and prevent any adverse effects on the pump or the pumped fluid.

5. Material Selection:

The choice of materials used in the construction of gear pumps can also contribute to their ability to handle variations in fluid viscosity. The materials should be selected based on the compatibility with the range of viscosities and potential chemical properties of the fluids being pumped. Proper material selection helps ensure that the pump can effectively handle the fluid without significant variations in flow rate or delivery accuracy.

In summary, gear pumps handle variations in fluid viscosity through their positive displacement operation, designed viscosity range, self-priming capability, consideration of temperature effects, and appropriate material selection. These features make gear pumps versatile and reliable for pumping fluids with different viscosities in various applications.

How do gear pumps contribute to accurate and consistent fluid delivery?

Gear pumps play a crucial role in ensuring accurate and consistent fluid delivery in various applications. Here’s a detailed explanation:

1. Positive Displacement Operation:

One of the key factors that contribute to accurate and consistent fluid delivery is the positive displacement operation of gear pumps. Gear pumps trap and displace a fixed volume of fluid with each revolution of the gears. This means that the pump delivers a consistent flow rate regardless of changes in pressure or viscosity. The positive displacement action ensures that the same amount of fluid is moved with each rotation, resulting in accurate and consistent fluid delivery.

2. Tight Clearances:

Gear pumps have tight clearances between the gear teeth and the pump housing, which helps minimize leakage and ensures precise fluid delivery. The close tolerances reduce the amount of fluid bypassing the gears, resulting in minimal slippage and accurate volumetric output. These tight clearances also contribute to the pump’s ability to handle high pressures and maintain consistent flow rates under varying conditions.

3. Low Pulsation:

Gear pumps are known for their low pulsation characteristics, which further enhance accurate and consistent fluid delivery. The meshing of gears creates a continuous and smooth flow of fluid, minimizing pressure fluctuations or pulsations in the system. This low pulsation flow is particularly important in applications where precise control, metering, or dosing of fluids is required.

4. Viscosity Handling:

Gear pumps are capable of handling fluids with a wide range of viscosities, from low-viscosity liquids to highly viscous fluids. This versatility in viscosity handling contributes to accurate and consistent fluid delivery. The positive displacement operation of gear pumps ensures that the pump can effectively move fluids of different viscosities without significant variations in flow rate or delivery accuracy.

5. Material Selection:

The choice of materials used in the construction of gear pumps can also impact accurate and consistent fluid delivery. The materials should be selected to minimize wear, corrosion, or contamination that could affect the pump’s performance or compromise the quality of the delivered fluid. Proper material selection ensures that the pump maintains its dimensional integrity and tight clearances over time, allowing for reliable and consistent fluid delivery.

6. System Integration:

Proper integration of gear pumps into the overall fluid system is essential for accurate and consistent fluid delivery. The system should include appropriate components such as filters, valves, and flow control devices to regulate and control the flow rate, pressure, and other parameters. By ensuring proper system integration, gear pumps can contribute to accurate and consistent fluid delivery throughout the entire system.

In summary, gear pumps contribute to accurate and consistent fluid delivery through their positive displacement operation, tight clearances, low pulsation characteristics, viscosity handling capabilities, appropriate material selection, and proper system integration. These features make gear pumps reliable and efficient in applications where precise fluid delivery is essential, including metering, dosing, lubrication, and other industrial processes.

Can gear pumps be used for both high-pressure and low-pressure applications?

Yes, gear pumps can be used for both high-pressure and low-pressure applications. Here’s a detailed explanation:

1. High-Pressure Applications:

Gear pumps can be designed and configured to handle high-pressure fluid transfer. By adjusting various parameters such as gear size, tooth profile, operating speed, and material selection, gear pumps can generate the necessary pressure to meet the requirements of high-pressure applications. The close tolerance design and efficient sealing mechanisms of gear pumps contribute to their ability to handle high pressures without excessive leakage or loss of performance.

2. Low-Pressure Applications:

Similarly, gear pumps are also suitable for low-pressure applications. The positive displacement operation of gear pumps allows them to deliver a consistent flow rate even at low pressures. Gear pumps can efficiently handle low-viscosity fluids and transfer them with precision, making them suitable for applications that require accurate metering or low-pressure fluid circulation. Additionally, the compact size and simplicity of gear pump design make them convenient for low-pressure systems where space and simplicity are important considerations.

3. Pressure Control:

Gear pumps can incorporate pressure relief valves or bypass mechanisms to regulate and control the pressure within the system. These features allow gear pumps to adapt to varying pressure requirements and protect the pump from excessive pressure build-up. Pressure relief valves can be set to open and divert excess fluid when the system reaches a specified pressure, ensuring safe and reliable operation in both high-pressure and low-pressure scenarios.

4. System Integration:

Gear pumps can be integrated into different hydraulic or fluid systems to accommodate various pressure levels. They can be used as standalone pumps or as part of a larger system, working in conjunction with other components such as valves, filters, and control devices. The flexibility and versatility of gear pumps make them adaptable to a wide range of pressure requirements across different industrial applications.

5. Application Considerations:

When selecting a gear pump for a specific application, it’s essential to consider the desired pressure range, flow rate, viscosity, and other system requirements. Proper sizing, material selection, and configuration of the gear pump will ensure optimal performance and longevity in both high-pressure and low-pressure applications.

In summary, gear pumps can effectively handle both high-pressure and low-pressure fluid transfer applications. Their design versatility, pressure control options, and ability to integrate into various systems make gear pumps a reliable choice for a wide range of pressure requirements in different industries.

editor by CX 2024-03-26